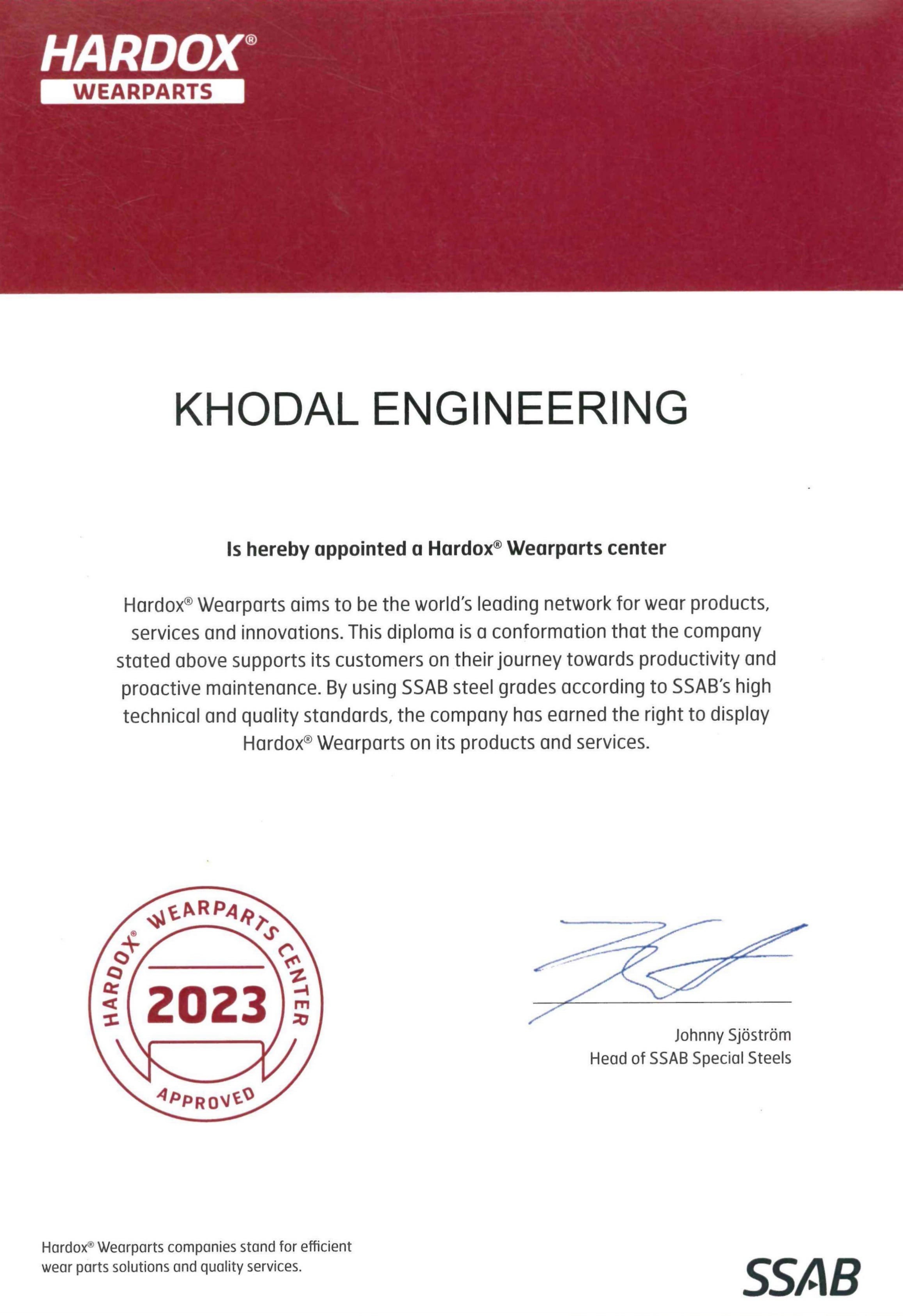

Hardox® Wearparts

Khodal Engineering is part of a distinguished network

of suppliers certified by SSAB. As a member, we have

access to the toughest, strongest, most high-quality

steel in the world.

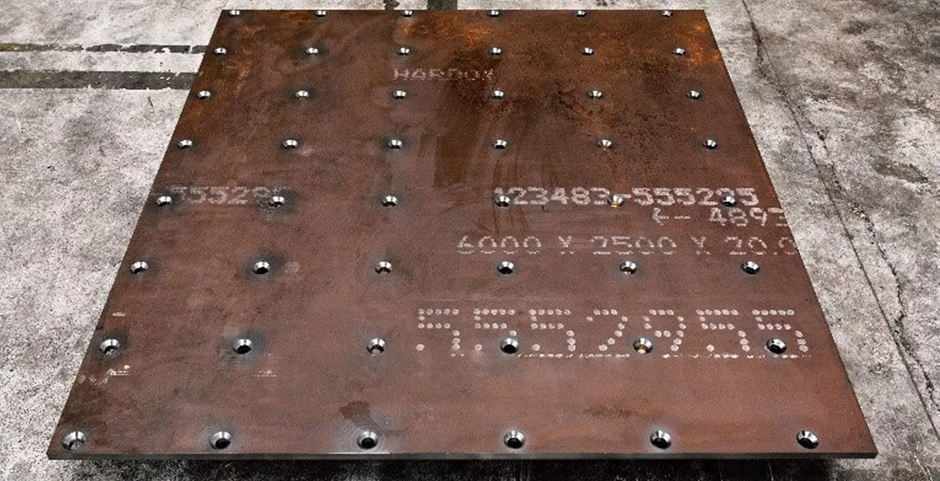

Hardox® Wear plate can withstand the most extreme

environments, providing advanced abrasion resistance,

and extra payload with a longer service life. Hardox®

wear plate is the international leader in abrasion-

resistant steel, guaranteeing tight bending, thickness

tolerances, and flatness tolerances. In addition, SSAB

continues to develop production processes to provide new

and improved products.

Khodal Engineering excels in the manufacturing of

Hardox® linear plates, offering top-quality solutions

for a wide range of industrial applications. With a

focus

on precision engineering and cutting-edge

technology, we deliver linear plates that are known

for their exceptional durability and wear resistance.

Whether it's for construction, mining, or heavy

machinery, Khodal Engineer's liners plates

are trusted for their robust performance and

reliability, making them a preferred choice for those

seeking superior materials in their projects.

-

We are a renowned manufacturer specializing in the

production of industrial Hardox screen plates.

-

With a deep understanding of the demanding

requirements these components face across various

industrial applications, we create high-quality,

wear-resistant screen plates known for their

durability and exceptional performance.

-

Our expertise in working with Hardox® steel,

celebrated for its strength and resistance,

guarantees customers receive screen plates capable

of withstanding tough conditions.

-

Count on us for top-tier Hardox® screen plates that

enhance your screening processes, reducing

maintenance needs and ensuring smoother industrial

operations.

We are a trusted manufacturer of high-quality Hardox®

limestone mill parts. We understand the critical role

these components play in crushing and grinding

processes, and our expertise in working with Hardox®

steel ensures durability and wear resistance. By

choosing our parts, you can count on improved longevity

and efficiency for your limestone mills, reducing

downtime and enhancing overall operations. Trust us for

top-tier Hardox® limestone mill components.

.png)

.png)